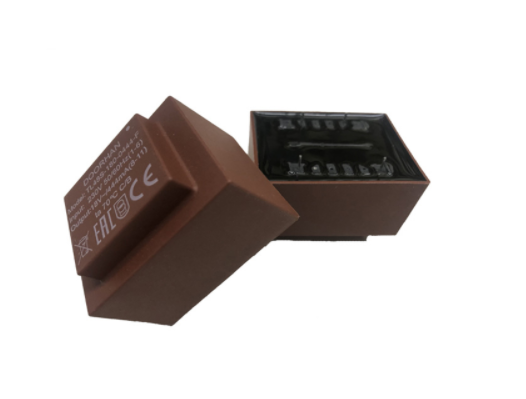

The encapsulated unit is covered with a thicker insulating coating than is typical. Typically, the coils are completely encapsulated in epoxy resin or a mixture of epoxy resin and aggregate. Sometimes they are referred to as "potted" or "cast coils".

The encapsulated design is particularly suitable for installations in harsh environments where dust, lint, moisture and corrosive contaminants are present. Typical applications include: pulp and paper mills; steel mills; food processing plants; breweries; mines; marine and shipboard installations.

If you're looking for the right transformer for your industrial facility, it's a good idea to familiarize yourself with the many benefits of encapsulated transformers.

It is important to protect the coils and cores within industrial transformers from debris and other contaminants. Overexposure to such contaminants will lead to eventual transformer failure. Periodic exposure over time will cause the transformer to wear out and require replacement of the transformer as soon as possible.

Encapsulated transformers avoid exposure to debris over time and tend to have a longer service life. As a result, they can save money in industrial operations and prevent inconvenient maintenance needs.

It is important to keep any type of electrical equipment dry to ensure proper operation and to prevent fire and electrical hazards.

Encapsulated transformers prevent water and moisture exposure. This type of transformer is safer to use than a regular transformer that does not include an epoxy or sand-bound cover.

Using encapsulation to protect against moisture not only prevents electrical problems. It also prevents corrosion from wearing out the coils and cores inside the transformer.

Ordinary transformers may not perform well in very harsh conditions. If you are unable to operate during inclement weather, it can reduce your productivity and bottom line.

With encapsulated transformers, your industrial operations can be performed in any condition and you can remain productive at all times.

One event that can seriously impact the productivity and profitability of an industrial facility is downtime caused by equipment failure.

Since the encapsulating transformer is less likely to suffer wear and tear or failure, it will experience less downtime and help increase the productivity of your industrial facility.

It is also important to note that package transformers do not need to be replaced as often. Therefore, they can help industrial facilities save money when purchasing replacement parts.

The encapsulate transformer is manufactured with high-quality EI type silicon steel sheets. It has the characteristics of low no-load loss, high power, high efficiency and low temperature rise. Specifications and parameters can be customized according to customer designed requirements. Please visit Sitong website for more products and contact us for the quote.