Summer is the peak of electricity consumption, then this time is very test store transmission equipment, and transformers as an important part of the transmission and distribution equipment, playing a role in changing the voltage and current, is vital, so the use is also very frequent. Because of this, the chances of transformer failure in the summer peak electricity consumption period will greatly increase, then the chances of failure also become larger, the following follow Sitong to see what should be done when the transformer failure occurs!

Transformer after shutdown power supply or trial power supply, often found that the voltage is not normal, such as two-phase high a phase low or indication of zero; some new commissioning transformer three-phase voltage are very high, so that some of the power equipment due to high voltage and burned.

In the new substation, according to the specifications should be timely installation of high and low voltage fuses. In the operation of the transformer, the fuse should be replaced in time after it is found to be burned or stolen.

High-voltage fuse blows to send no power.

Reasonable configuration of high and low voltage fuses.

① capacity in more than 100kVA transformer to configure 1.5 ~ 2.0 times the rated current fuse;

② capacity of the transformer below 100kVA to configure 2.0 ~ 3.0 times the rated current of the fuse;

③ low voltage side fuse should be slightly larger than the rated current selection.

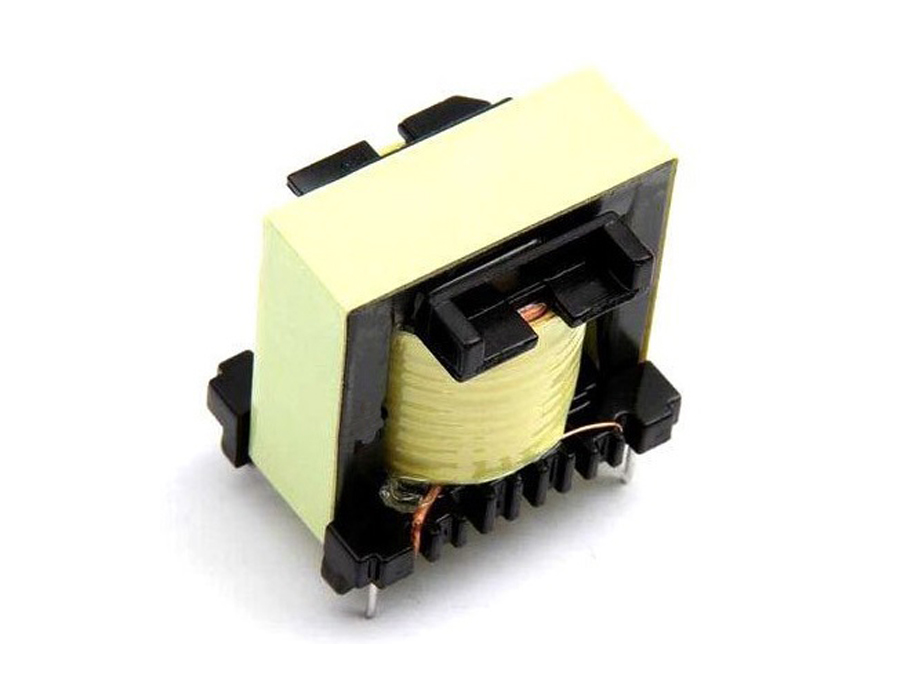

Sitong EI35 isolated transformer

Transformer can not send power after a thunderstorm.

Strengthen the actual measurement of power consumption load, use the clamp-on current meter to measure the load of each distribution transformer when the peak period comes, reasonably adjust the load, and avoid unbalanced operation of the distribution transformer in three phases.

Transformer sound is not normal, such as a "squeak" or "thunder" sound; in operation, such as frogs "ki wah ki wah" sound, etc.

For 10kV distribution substation voltage on the low-voltage side of the +7% to -10% range, generally do not allow adjustment of the tap changer. Adjustment of the tap changer, to be adjusted by the repair and testing technicians test.

High-voltage terminals burned, high-voltage casing with serious signs of damage.

Regularly check whether the three-phase current is balanced or exceeds the rated value. If the three load currents are seriously imbalanced, timely measures should be taken to adjust.

Under normal cooling conditions, the transformer temperature is out of whack and rising.

Before the annual thunderstorm season comes; the lightning arrester on all distribution transformers should be sent to the repair and testing department for testing and timely installation after passing the test.

The oil color changes too much, and charcoal appears in the oil.

The following tests should be done before commissioning.

① with a load to divide and close the switch three times, shall not be misdirected;

② Test with test button three times, and it should be operated correctly;

③ test with test resistance grounding three times, should be correct action.

Transformer roar, from the safety air channel, oil storage cabinet to spray oil, oil tank and heat pipe deformation, oil leakage, oil seepage, etc.

Regularly clean up the dirt on the surface of the distribution transformer casing, check whether the casing has flashing traces, whether the grounding is good, whether the lead used for grounding has broken strands, desoldering, fracture phenomenon, and the grounding resistance shall not be greater than 4Ω detected by megohmmeter.

Does the above sharing solve your problem? If your transformer always encounter failure, then we recommend you or timely replacement, if you do not know which model of transformer to choose or want to get a higher quality and lower price of transformer equipment, please contact Sitong!