Due to the use of electricity (current) as the main resource for production, many industrial applications require specific industrial transformers. These are called special purpose or industrial transformers and their design is tailored for high current solutions for industrial applications.

EAF and LF transformers are required for and applications. They are built for, and are similar to short arc furnace or submerged arc furnace transformers.

For long-arc steel furnace operation, additional series reactors are often required to stabilize the arc and optimize operation of the furnace application process.

EAF transformers are rigorously designed to withstand repeated short-circuit conditions and high thermal stresses, and to prevent operating overvoltages generated during the arcing process.

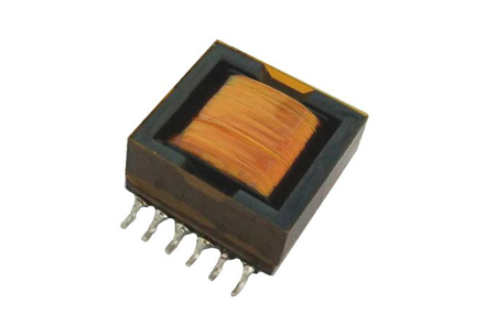

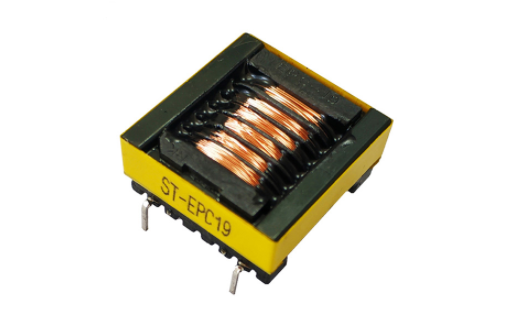

EFD High Frequency Transformer

DC Electric Arc Furnace (DC EAF) transformers are required in many different furnace processes and applications.

They are built for steel furnaces with thyristor rectifiers. DC EAF transformers operate under very harsh conditions, just like a normal rectifier transformer, but with rectifier transformers for furnace operation. The load is cyclic.

Rectifier transformers are combined with diode or thyristor rectifiers. Their applications range from very large aluminum electrolysis to a variety of medium sized operations.

The transformers can have a built-in or separate voltage regulation device. Due to the wide variety of applications, they can have various designs, up to a combination of voltage regulation, double-stack configuration of rectifier transformers, phase shifting, phase-to-phase reactors, transistors and filter windings.

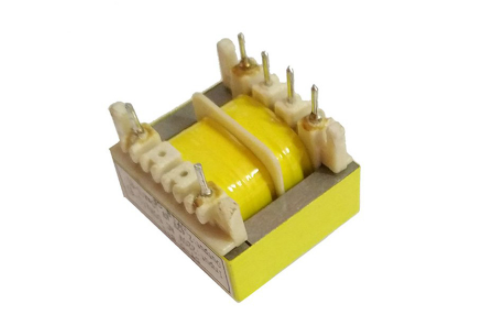

EI Pin Low Frequency Transformer

Converter transformers - The drive systems used in converter transformers can drive a variety of applications such as pumping stations, rolling stock and wind tunnels in the mining industry, and blast furnaces. Converter transformers can be used for large drive applications, static voltage compensation and static frequency variations.

Most of the converter transformers are of double-layer construction with two secondary windings, allowing rectification operation of 12 pulses. Such transformers usually have an additional winding as a filter to remove harmonics. Different vector sets and phase shifts are possible.

This transformer implements the connection between the power network and the train power supply. The transformer operates every year under specific critical short-circuit conditions and overload conditions with very high frequencies, requiring higher reliability for safe train operation.

The direct connection between the transmission network and the railroad overhead contact line changes the frequency by means of a DC conversion. These contain thyristor or diode rectifiers, as well as air or water cooling.

SITONG is a professional manufacturer for all kinds of transformers, such as isolated transformers, encapsulated transformers, 50/60Hz transformers, power transformers, inductors and coils. Based on the policy of stringent quality, and credibility of the business, we will satisfy each customer with the perfect service and best products. Feel free to contact us and we offer great price for you.