With more efficient and smaller power supplies powering electrical devices, high-frequency transformers are a key component in powering modern electronic devices.

The market forces driving the proliferation of electronics into more and more applications stem from more than half a century of continuous design innovation. With high-frequency transformers, understanding how to minimize skin effect, proximity effect and losses due to the type of core material used is critical. It can have a profound impact on the ultimate performance and success of a design.

High frequency transformers work using the same basic principles as standard transformers. The main difference is that, as the name implies, they operate at much higher frequencies - whereas most line voltage transformers operate at 50 or 60 Hz, high-frequency transformers use frequencies from 20 kHz to over 1 MHz.

There are many benefits to operating at higher frequencies, starting with size. For any given power rating, the higher the frequency, the smaller the transformer can be. Second, because the transformer is smaller, less copper wire is required, which reduces losses and helps improve the efficiency of the transformer. In addition, because the cores are typically ferrite, a variety of geometries can be used, making it possible to tailor the transformer to the application. Regardless of whether additional shielding or a specific form factor is required, ferrite cores are likely to meet the requirements.

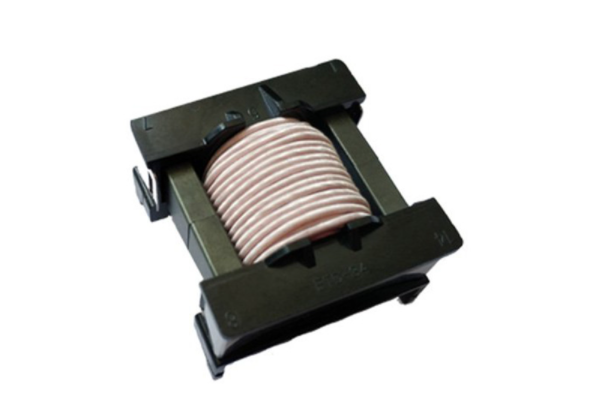

ETD High Frequency Transformer

The benefits of light weight, small size and higher power density present many challenges. Minimizing issues such as skinning and proximity effects is a serious concern when designing high frequency transformers.

is caused by the tendency of high frequency currents to flow over the surface of a conductor. Losses due to skin effect can be reduced by using Leeds wires. Leeds wire is constructed by "braiding" multiple smaller conductors together to form an equivalent larger gauge.

Also known as eddy current loss, this is caused by magnetic fields from adjacent conductors in adjacent windings, or of more serious concern in adjacent layers, which can cause current to flow in unintended patterns or eddy currents. This effect can create excessive resistance and unintentional power loss within the wire.

As transformers become smaller and power densities increase, heat dissipation can become a major design obstacle, despite higher efficiency. In many cases, fans are needed to increase airflow or active cooling by mounting the transformer on a cooling plate. Potting is also common in thermally conductive materials.

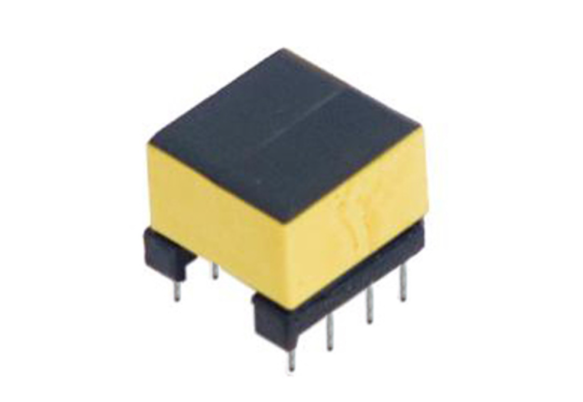

EPC Flyback Transformer

Several formulas are used to accurately calculate the mechanical dimensions of high-frequency transformers; they are based on two factors: the amount of power to be transmitted and the operating frequency. Just a few years ago, a frequency range of 50-100 kHz was the norm. Today, however, frequencies of up to 400-500 KHz or even 1 MHz are possible.

These higher frequencies make transformers smaller in size, using a smaller Ae (core cross section) for any given number of turns. In practice, the design engineer must balance this equation so that as the frequency increases, smaller cores and fewer turns are required to operate at the desired flux density.

Select the right core.

Calculate the number of primary turns required based on the flux density at which the engineer chooses to operate.

Calculate the number of secondary turns, expressed as the ratio of primary to secondary voltage.

EP17 Transformer

In addition, when dealing with high frequency transformers, the designer must ensure that the wire thickness does not exceed two times the skin depth at that frequency. As the frequency increases, more current will flow to the outside of the wire, resulting in skinning effects.

High frequency transformers are used in a variety of advanced applications, large and small, from powering personal computers to powering homes and commercial properties. If you are looking for a reliable manufacturer, please contact us.