RM6 Transformer

Specification

1. Working frequency: 20kHz -500kHz

2. Output power: 4 to 20W

3. Working temperature: -40℃ to +125℃

4. Storge temperature: -25℃ to +85℃

5. Storge humidity: 30 to 95%

PRODUCT DESCRIPTION

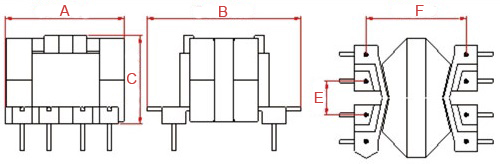

RM6 TYPE 1

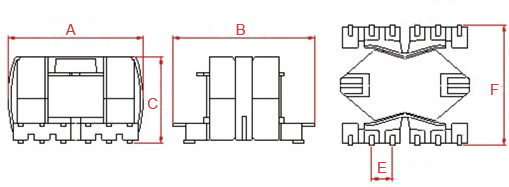

RM6 TYPE2

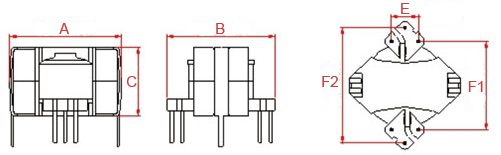

RM6 TYPE3

| Type | Structure | Dimension(mm) | Pin Row(mm) | Row Pitch(mm) | OD Pin(mm) | Note | |||

| A | B | C | Pin | E | F1/F2 | ||||

| RM06-01 | Vertical | 19.0 | 24.5 | 14.5 | 4+4 | 4.0 | 15.0 | Φ0.5 | TYPE 1 |

| RM06-02 | Vertical | 21.0 | 21.5 | 14.0 | 6+6 | 3.0 | 18.1 | SMD0.7 | TYPE 2 |

| RM06-03 | Vertical | 21.0 | 21.0 | 13.5 | 3+3 | 3.6 | 14.4/18.0 | Φ0.5 | TYPE 3 |

Specifications and parameters can be customized according to customer designed requirements.

High Frequency Transformer Product Description

High frequency transformer is a kind of electronic transformer which work frequency exceed 10 kHz, it widely used in switch power supply, inverter power supply, power meters, Telecom, inverter welding machine and photovoltaic, etc.

High frequency transformer as the most important parts in switch power supply, there are so many topological structures, such as forward full/half Bridge structures.

Sitong Electronic not only could manufacture forward half/full bridge transformers, also have other circuit transformers, such as flyback transformers, converter transformers, inverter transformers, push-pull transformers, LLC transformers, etc.

Advantage:

1. Our materials resource from the suppliers in our UL lists (UL E364966). They have passed RoHS certificate. If you have pointed supplier, it is also available. We will inform in advance if there are any changes about the materials or suppliers.

2. Sitong Electronic has passed ISO9001:2015, our procedures according to the ISO requirements strictly. Our SOP is same as the customer’s requirements, and the batch goods are same as the delivered samples.

3. The goods will be inspected 2 times before delivery to ensure the best quality: All the products will through testing before varnish, and will be 100% tested before package. Twice testing including: turns, inductance, Hi-pot, leakage inductance, DCR, visual inspection, etc.